O v e r v i e w

Project: Lincoln MKT 2008 Concept Car Interior

Time: 2006 - 2007

Credit: Interior Design Manager

This design process was a labor of love. We faced numerous challenges in creating this unconventional interior, executing fluid shapes in a minimalist manner to achieve a cohesive, naturally flowing aesthetic that encapsulates visual appeal.

Spacious Elegance - This is how I can best describe it. The Lincoln MKT concept offers a sense of freedom with seats inspired by first-class cabins. Four executive-sized chairs provide more comfort and legroom than before. For added pleasure, the second row features heated and cooled thigh supports and footrests that deploy from the front seats, allowing passengers to fully recline.

R e s e a r c h & I n s p i r a t i o n

I envisioned the concept as a "modern Learjet for the road," blending high-end utility for businessmen and families alike.

The symmetrical interior design ensures equal access for all four passengers.

Innovative semiconductor technology in the center console projects light in 3D, allowing for unique shapes and storage spaces.

C o n c e p t D e v e l o p m e n t

Idea Generation: I brainstormed with the team and generated ideas based on market research. Sketching and Digital Renderings were made to visualize the concept. We designed with functionality at its core, the center console showcases a multifunctional design that serves as a traditional armrest while incorporating a rotational mechanism for optimal space utilization. This innovative console houses all the electronic components required for a fully operational screen, ensuring a sleek, high-tech user experience with everything elegantly contained within.

I n s p i r a t i o n

My inspiration for the dashboard and two-level center console was inspired by Swarovski crystals, with LEDs creating a radiant effect.

P r o t o t y p i n g - Step 1

.

3D Modeling: The team develop a 3D model using Elias software.

Design Review: We conducted reviews to meet aesthetic and functional requirements.

Engineering Feasibility: I ensured the structural integrity, aerodynamics, and manufacturability with the DTO team.

P r o t o t y p i n g - Step 2

Clay Modeling: Full-scale clay model for physical visualization and adjustments.

· Rapid Prototyping: Use 3D printing for parts and components.

· Interior Mock-up: Create an interior mock-up to test ergonomics and user experience.

P r o t o t y p i n g

Finished prototype. Created to refine the concept and test functionality, aesthetics, and usability. This process facilitated further evaluation and adjustments based on user feedback and performance assessments before moving on to final production, ensuring that the design meets all specifications and effectively addresses user needs.

Iteration and Refinement:

Feedback Integration: Incorporate feedback from testing.

Prototype Refinement: Make design and engineering adjustments.

Final Approval: Obtain approval from stakeholders.

Pre-Production:

Manufacturing Planning: Plan tooling, assembly, and logistics.

Pre-Production Build: Create pre-production units for quality control.

Materials Selected

We paid special attention to ensure the use of high-end materials throughout the entire interior of the concept vehicle, creating an upscale and refined environment.

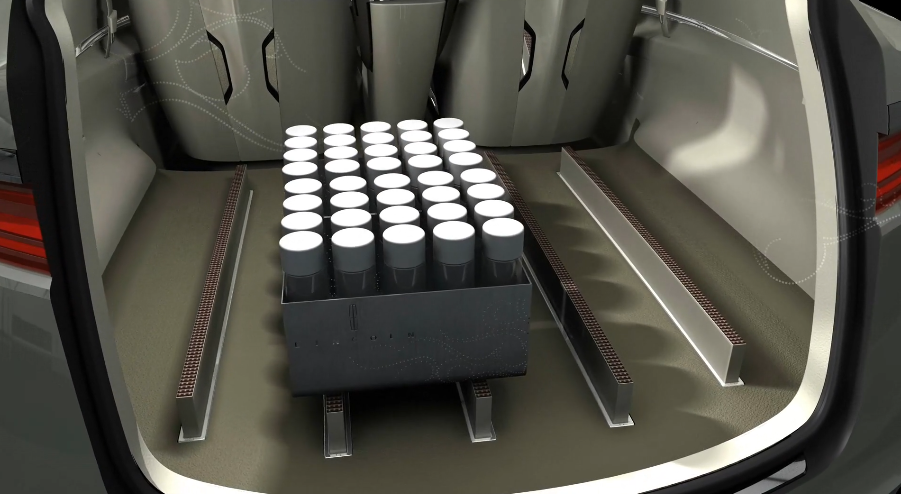

P a t e n t e d

Rafael designed and executed a unique and revolutionary trunk space featuring automated adjustable racks that enhance functionality and versatility. The design includes automated flat and adjustable flooring, along with customizable storage dividers, all while effectively restricting movement within the trunk area. This innovative approach resulted in the granting of a functional patent.

C o n c e p t R e f i n e m e n t

In this process, we focus on enhancing and fine-tuning the initial design concepts to achieve optimal functionality and aesthetic appeal. This involves gathering feedback, analyzing user needs, and exploring innovative solutions. Through iterative testing and collaboration, we refine the details, materials, and overall design, ensuring that the final product aligns with both the brand vision and user expectations. This stage is crucial for transforming initial ideas into a polished and effective solution that meets all intended goals.

High-quality materials were utilized throughout, featuring leather-trimmed seating surfaces

F i n a l P r o d u c t

From strategy to design and the creation of a concept vehicle. The Lincoln MKT, which debuted at the 2008 Detroit International Auto Show, garnered significant media attention and served as the primary inspiration for the production vehicle.